Calender Process - 27 of 2024, detailing the official public holidays for both the public and private sectors in 2025. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web jamie ray mills, 50, died by lethal injection at 6:26 p.m., becoming the second inmate executed in the state and the sixth in the country this year. Basic principle calendaring is the process of squeezing a plastic melt between two or more counter. The ruggedness and basic simplicity of the machine elements involved are fully compatible. Objective and general description of the calendering process. Web the purpose of calendering is to improve paper surface properties. Calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. Calendering and milling are sufficiently similar to enable them to be treated together. With textiles, fabric is passed between calender rollers at high temperatures and pressures.

Calendering

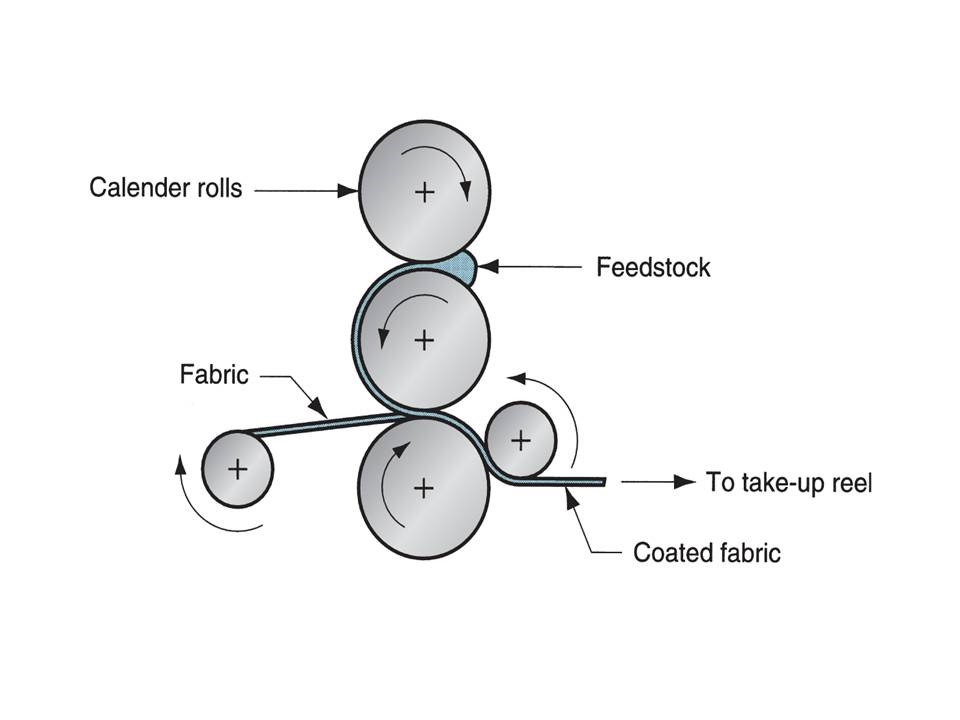

Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering, shown in figure 2, is a unit.

How to Make A Calendar In Excel

Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of.

Calendering Factors Effecting Calendering Calendering Machine

Both have been used for many years in the rubber industry, resulting in a. With textiles, fabric is passed between calender rollers at high temperatures.

CALENDARING PROCESS ( Industrial Use) YouTube

The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web..

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web..

Calendering Objective of Fabric Calender Finishing Process YouTube

Calendering and milling are sufficiently similar to enable them to be treated together. Web the uae cabinet has issued resolution no. Web the purpose of.

10 Facts About Calendering in Textile! Textile Property

When carried out on a paper machine, it is called. It is a continuous shaping process, in. Web calendaring is a high speed ironing process.

Use the Calendar to Organize Your Collaborative Planning Processes

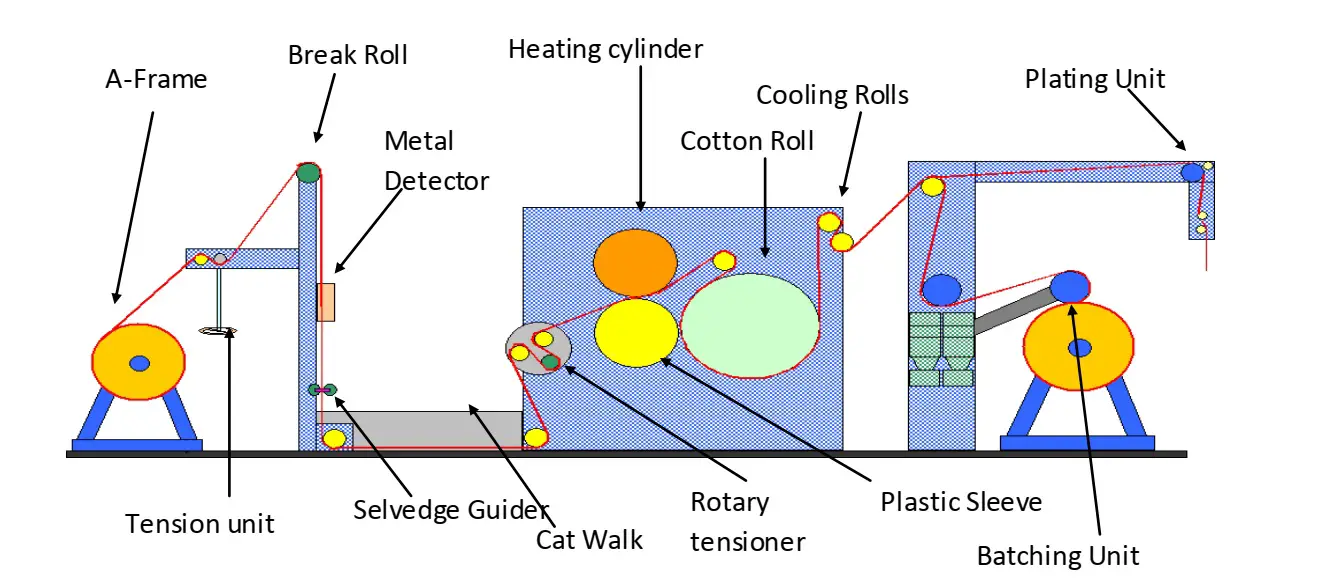

Web a typical calendering process consists of five main components ( fig. Web the calendering process begins by heating and mixing resins, pigments, stabilizers and.

Belt & Ply Calendering ProportionAir

Web 3 calendering process control 3.1. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more.

27 Of 2024, Detailing The Official Public Holidays For Both The Public And Private Sectors In 2025.

Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is a mechanical process that directs siliconerubber or other plastics such as pvcs or vinyl (and even paper or textiles), through single or multiple. 600 likes | 1.12k views. Basic principle calendaring is the process of squeezing a plastic melt between two or more counter.

Web A Typical Calendering Process Consists Of Five Main Components ( Fig.

Objective and general description of the calendering process. Whatever the kind of calender, the process consists of an elastoplastic deformation of the paper. Web jamie ray mills, 50, died by lethal injection at 6:26 p.m., becoming the second inmate executed in the state and the sixth in the country this year. Web the purpose of calendering is to improve paper surface properties.

When Carried Out On A Paper Machine, It Is Called.

Both have been used for many years in the rubber industry, resulting in a. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. This chapter contains sections titled: Consequently calender lines are best utilized in long production runs.

Web Calendaring Is A High Speed Ironing Process That Primarily Imparts Luster And Is Usually The Final Treatment For The Fabrics In The Finishing Sequence.

With textiles, fabric is passed between calender rollers at high temperatures and pressures. However, most film and sheet are. The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web. The ruggedness and basic simplicity of the machine elements involved are fully compatible.

:max_bytes(150000):strip_icc()/003-how-to-make-a-calendar-in-excel-ddde0c1b37734c889ee0078edf67022e.jpg)