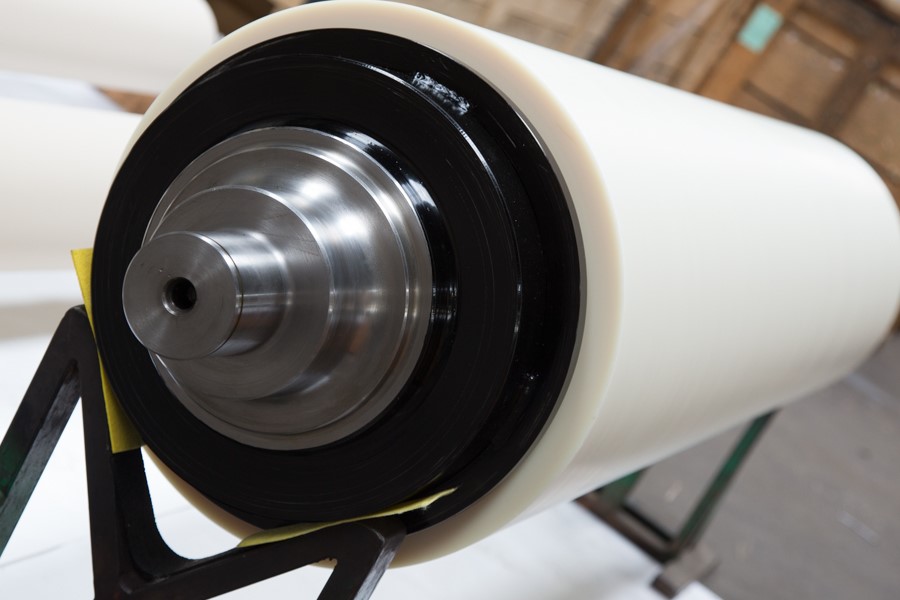

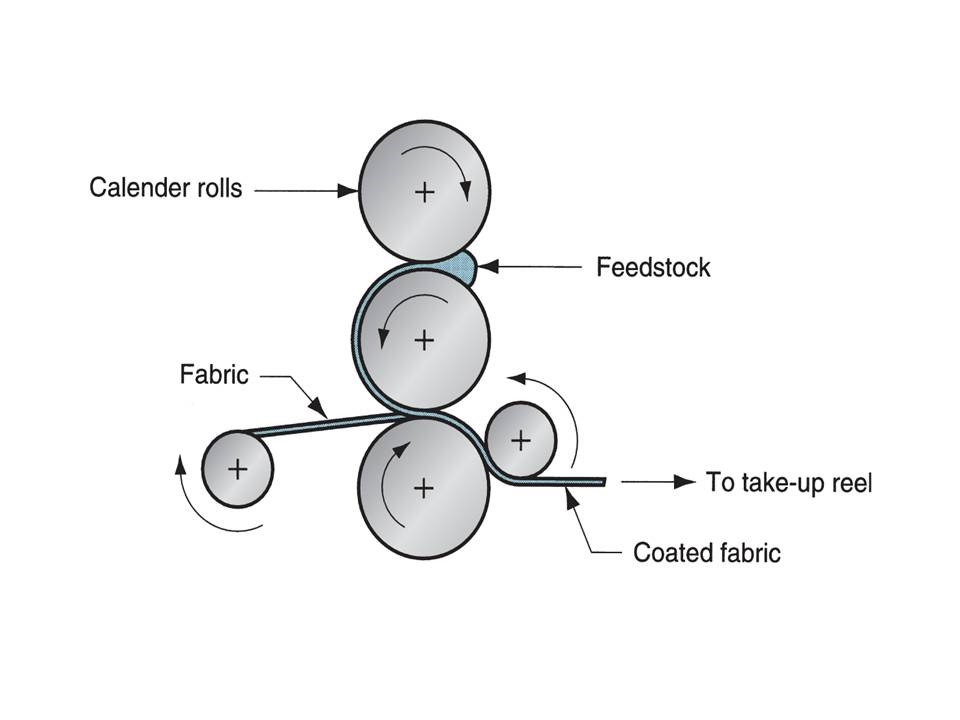

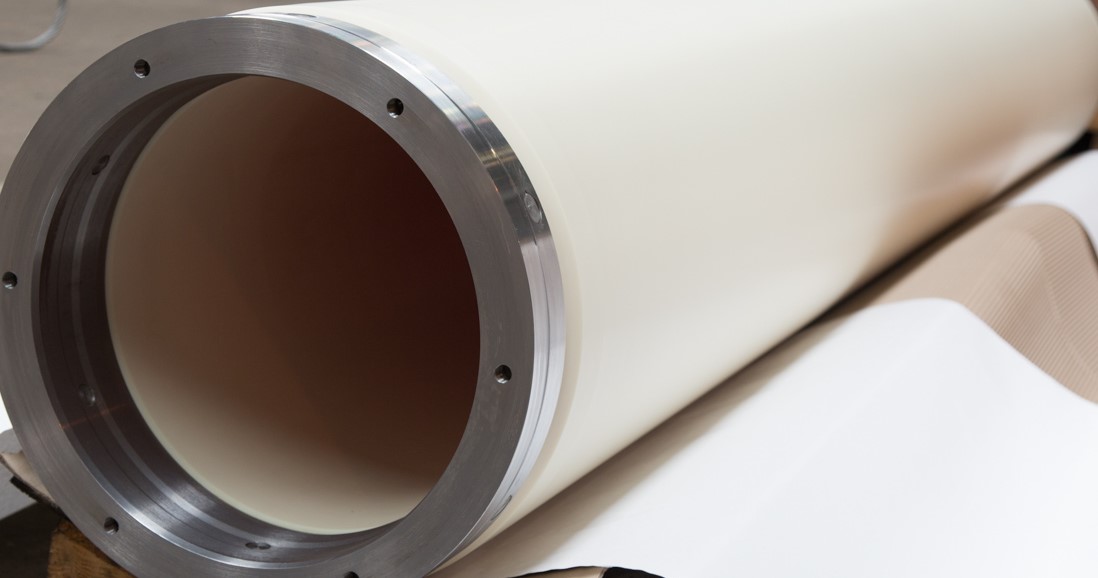

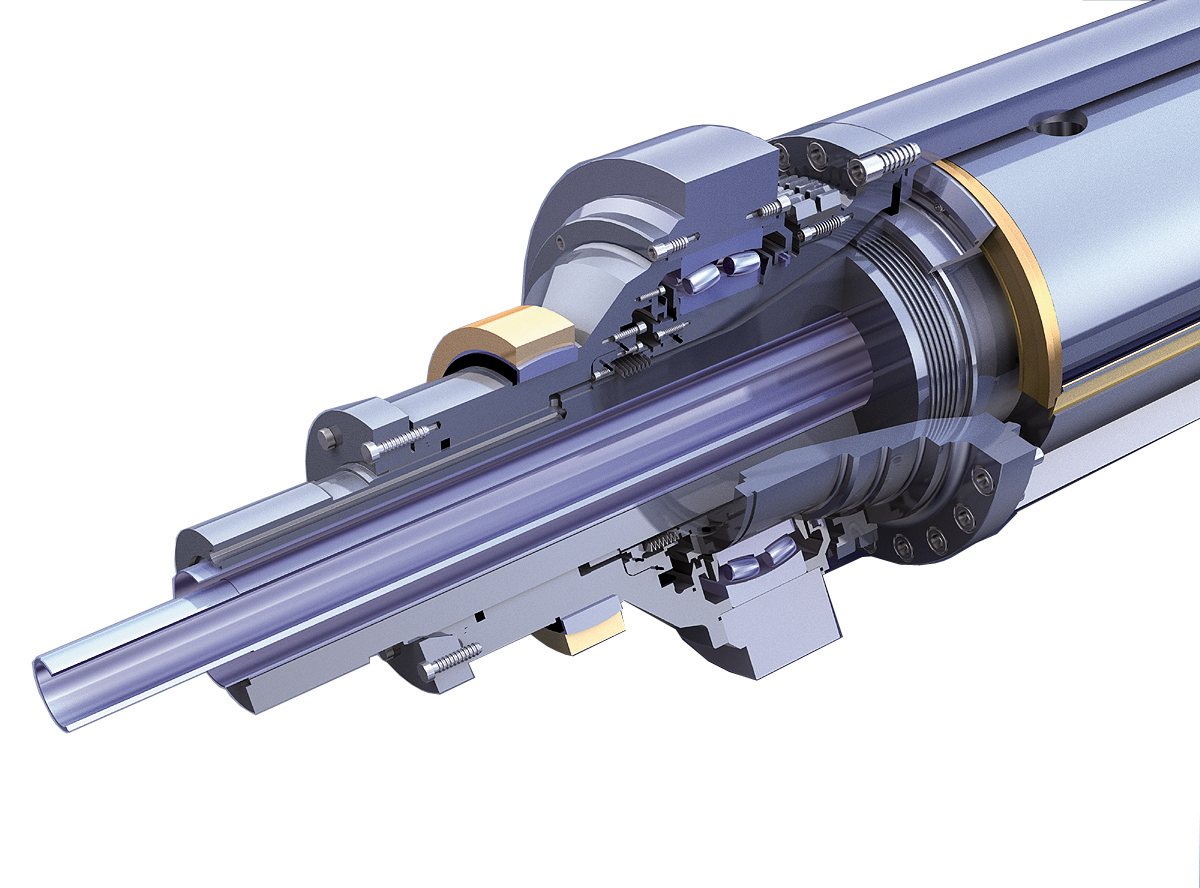

Calendering Rolls - Web 4 roll calender machine is one of the specifications of rubber calender machine, which is used for processing rubber, plastic, silicone and so on. Web one of the calender roll is usually made of stainless steel (which may be heated to the required temperature) while the other may be covered with highly compressed cotton, paper or synthetic material. Rubber sheeting is still produced by calendering, which has also become the. From eliminating paper defects to ensuring consistent gloss finishes, our coated rolls are providing benefits to paper mills around the world. The speed of the roll, the output/throughput, the temperatures of the rolls, the separating forces applied to the rolls and the input power of each roll. Web calendering and milling are sufficiently similar to enable them to be treated together. At least one roll is equipped with screwdowns to control the thickness of the processed material. The single largest application for reverse roll coating is applying architectural paint to coils of sheet metal; The kwf hilger gmbh & co. Rubber calenders consist of two or more hardened and accurately machined metal rolls rotating in bearing journal boxes which are set in rugged iron frames.

Nonwoven calendering performs crucial steps in manufacturing

Web calendering means the deformation of paper or board under pressure and temperature; Web calendering and milling are sufficiently similar to enable them to be.

Calendering Force Control on Calender Rolls by ProportionAir

With textiles, fabric is passed between calender rollers at high temperatures and pressures. Involves passing material through heated rollers for enhanced surface finish. Kg •.

Calendering rolls for the textile industry KWF Hilger

Kg • the german calender roll company. Web 4 roll calender machine is one of the specifications of rubber calender machine, which is used for.

Roll calendering machines our equipment Nicro

Web 4 roll calender machine is one of the specifications of rubber calender machine, which is used for processing rubber, plastic, silicone and so on..

Calendering rolls for the textile industry KWF Hilger

They also provide superior resistance to doctor blade wear and scratching. Involves processing materials without the use of liquids, often used for paper production. No.

Calendering rolls for the textile industry KWF Hilger

Rubber sheeting is still produced by calendering, which has also become the. They also provide superior resistance to doctor blade wear and scratching. Rubber calenders.

10 Facts About Calendering in Textile! Textile Property

Calendering is the forming of a thermoplastic mass between two or more rollers into a. Rubber sheeting is still produced by calendering, which has also.

Calendering rolls for the textile industry KWF Hilger

The speed of the roll, the output/throughput, the temperatures of the rolls, the separating forces applied to the rolls and the input power of each.

Calendering

It is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers at high temperatures and pressures. Rubber.

With Textiles, Fabric Is Passed Between Calender Rollers At High Temperatures And Pressures.

Utilizes unheated rollers to achieve smoothness without added heat. Common types of calendering machine used in the textile industry include: Web our coatings resist abrasive wear caused by fibers, fillers, coatings and contaminants in or on the paper. Rubber sheeting is still produced by calendering, which has also become the.

The Kwf Hilger Gmbh & Co.

At least one roll is equipped with screwdowns to control the thickness of the processed material. Smooth fabric surface can be obtained. No risk of displacing of fabric. It is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers at high temperatures and pressures.

Very High Glossy Fabric Is Achieved.

Web calendering is a basic unit operation used in both plastics and rubber compounding. Web the technological parameters of calendering may involve the following attributes: Rubber calenders consist of two or more hardened and accurately machined metal rolls rotating in bearing journal boxes which are set in rugged iron frames. Lighter gauge film at 0.18 mm (0.007 in) when leaving the last calender roll is typically drawn down at a ratio of 1.2/1 and wound up at a thickness of o.ismm (0.006in).

Kg • The German Calender Roll Company.

The rolls in combination are called calenders. Different from 3 roll calender machine, 4 roll calender has two pairs of rollers, one on top and one on bottom, which work together to process raw materials. Web calendering and milling are sufficiently similar to enable them to be treated together. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material.