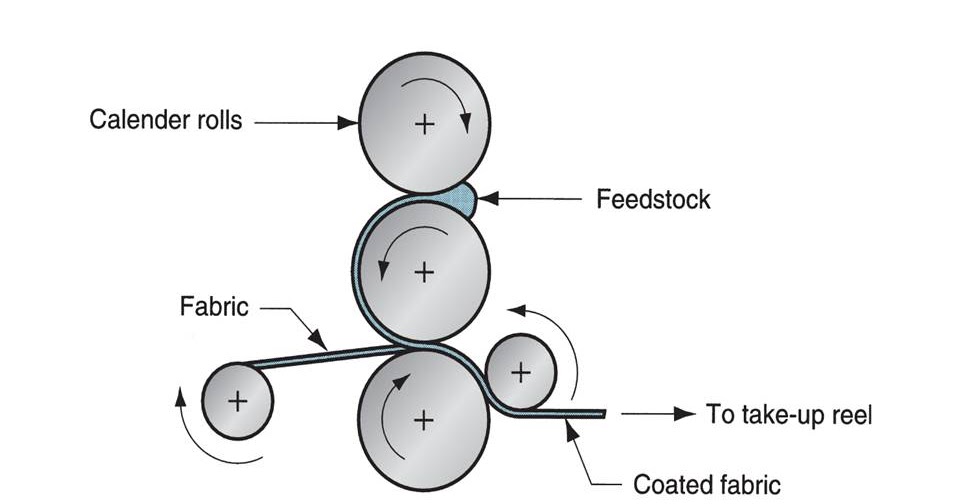

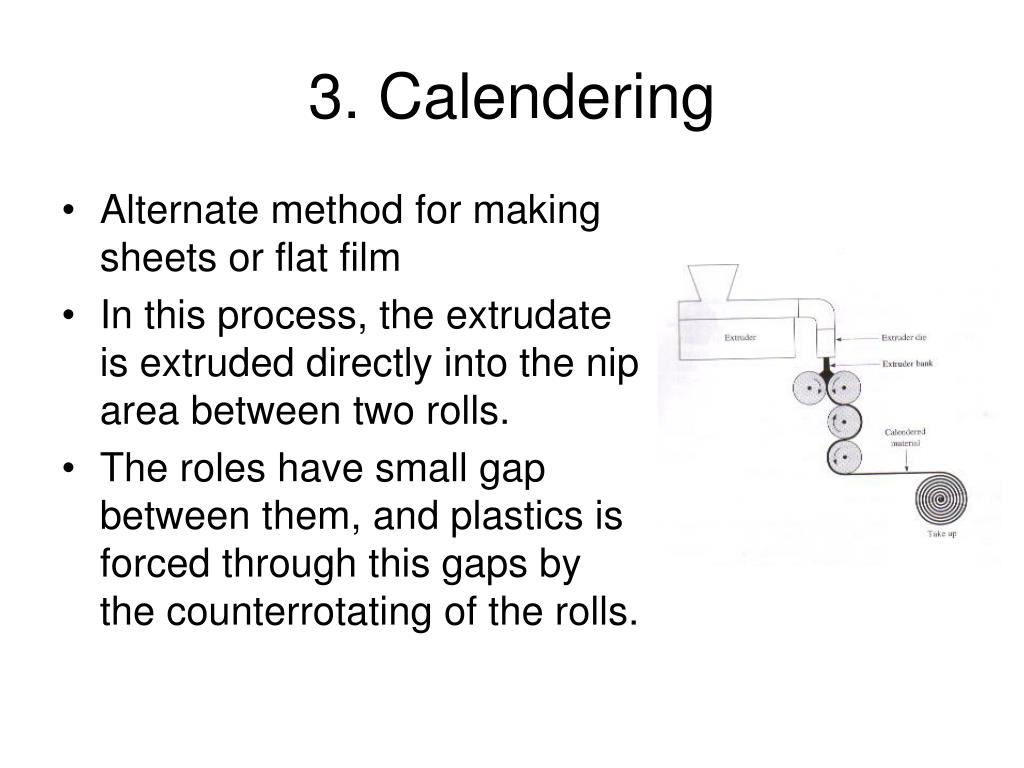

Define Calendering - Web the meaning of calender is to press (cloth, rubber, paper, etc.) between rollers or plates in order to smooth and glaze or to thin into sheets. However, most film and sheet are prepared by extrusion techniques (chapters 8 and 9). The rolls in combination are called calenders. In most cases the end products of the calendering processes are either sheets, films, or coated textiles. Objective and general description of the calendering process. Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. The rollers are typically made of steel or other hard materials and can be heated or. The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web.

Calendering

A machine for impregnating fabric with rubber, as in the manufacture of automobile tires. Web calendering is a process whereby fabric is compressed by passing.

PPT CALENDERING PROCESS PowerPoint Presentation, free download ID

Web a calender is employed, usually to smooth, coat, or thin a material. Web the meaning of calender is to press (cloth, rubber, paper, etc.).

Calendering

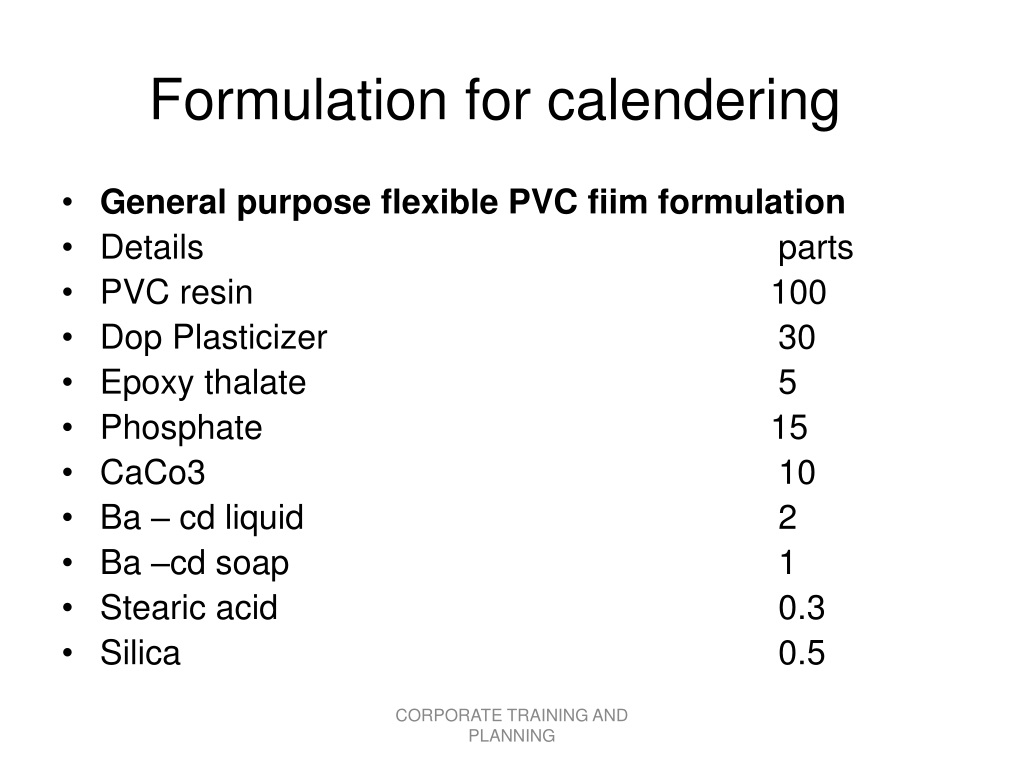

Web calendering involves thus both melting and shaping processes in one step. The melted polymer is subject to heat and pressure in an extruder and.

6 Types of Calendering Process in Textile ! Textile Property

K j hardman ceng m/meche mipiante amct imperial chemical industries ltd. Patented for processing potash in 1790. The quality aspects of the material include size.

PPT CALENDERING PROCESS PowerPoint Presentation, free download ID

Web calendering was originally developed to process rubber, but today is widely used to make thermoplastic films, sheets, and coatings. Web calendering involves thus both.

PPT ExtrusionBased Processes PowerPoint Presentation, free download

This chapter contains sections titled: Get the calendering correct and it will improve: In most cases the end products of the calendering processes are either.

Nonwoven calendering performs crucial steps in manufacturing

From french calandre, of unknown origin. The surface of rollers can be. Web calendering of textiles is a finishing process used to smooth, coat, or.

Properties of the Calendering Process Download Scientific Diagram

A machine in which paper or cloth is glazed or smoothed by passing between rollers. Web calender, machine that has wide application in the finishing.

Calendering

Web calendering means the deformation of paper or board under pressure and temperature; The final operation on a papermaking machine, performed to impart to paper.

However, Most Film And Sheet Are Prepared By Extrusion Techniques (Chapters 8 And 9).

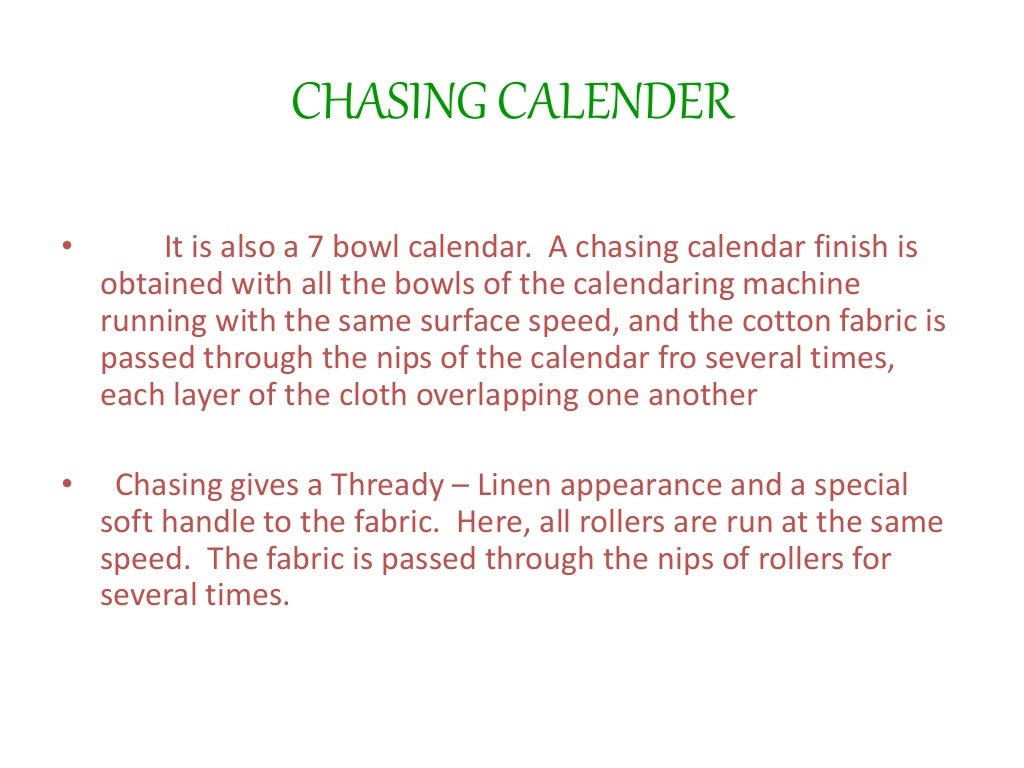

With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web calendering may be defined as the modification of the surface of a fabric by the action of heat and pressure. With textiles, fabric is passed under rollers at high temperatures and pressures. The surface of rollers can be.

Web Calendering, Process Of Smoothing And Compressing A Material (Notably Paper) During Production By Passing A Single Continuous Sheet Through A Number Of Pairs Of Heated Rolls.

First used to coat fabrics in 1874. Web calendering means the deformation of paper or board under pressure and temperature; Web a list of events and dates within a particular year that are important for an organization or for the people involved in a particular activity: Get the calendering correct and it will improve:

Web Calendering Involves Thus Both Melting And Shaping Processes In One Step.

Web calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. It is mainly done to impart lustre and smoothness to the fabric. The surfaces of the nipforming rolls are embossed onto the surface of the paper web. It is basically an embossing process.

Volumetric Energy Density, Cyclic Stability, Rate Capability Of The Cells And Also Enhance The Structural Stability Of The Active Material.

The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web. A machine in which cloth, paper, or the like is smoothed, glazed, etc., by pressing between rotating cylinders. Web calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. From french calandre, of unknown origin.