Forming Rolls And Calenders - Calendering and milling are sufficiently similar to enable them to be treated together. Valmet’s calender roll covers provide longer service intervals and optimum paper or board properties. Web therefore, when calendaring polymers, the material passes three nip regions. In case of calenders with two and three rolls, the rolls are normally arranged vertically over one another. Besides providing better marking resistance, our calender covers allow much higher speeds and temperatures without damage than conventional alternatives. Calenders are sometimes misspelled calendars. Web comprehensive calender roll services. Utilizes unheated rollers to achieve smoothness without added heat. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Explore a searchable database of us construction and building code.

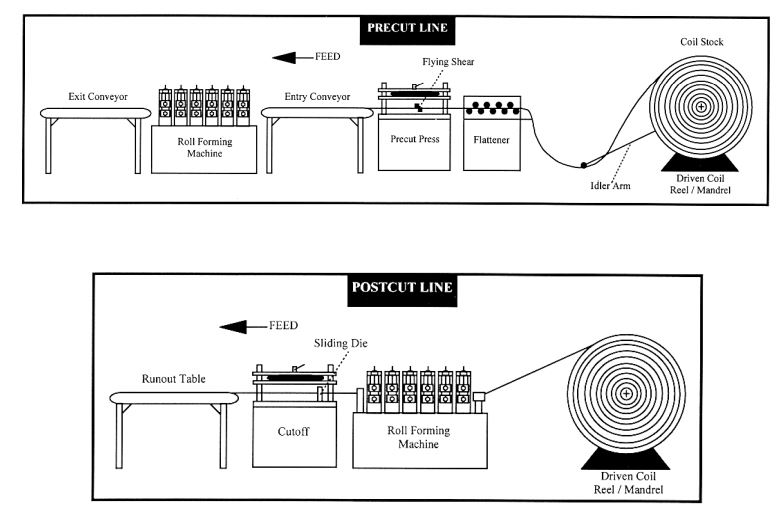

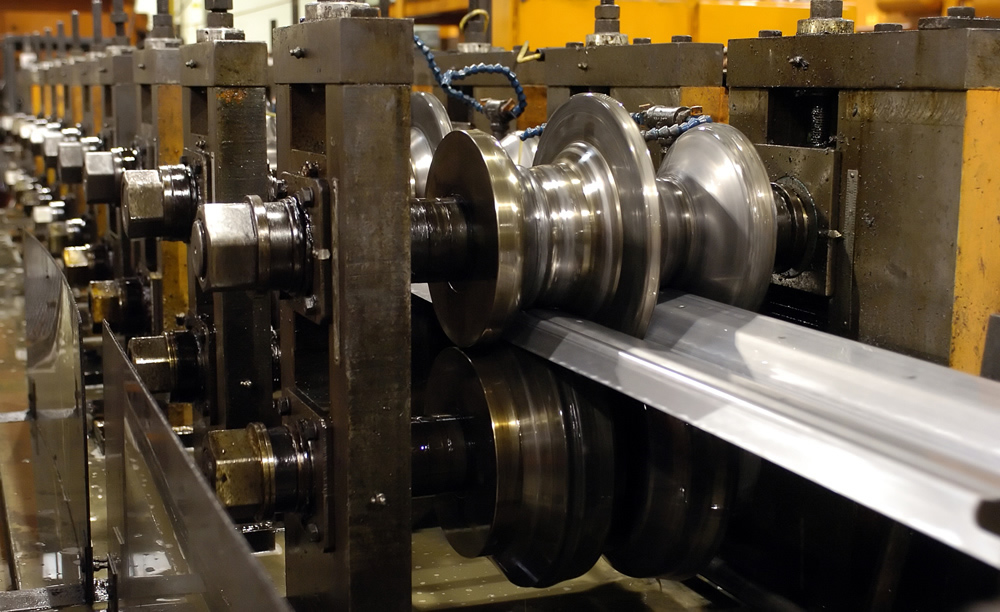

Roll Forming Operation Manual adjust a roll former

Web the calendering process begins by heating and mixing resins, pigments, stabilizers and plasticizers in an industrial mixer. Some calender rolls are heated or cooled.

Calendar stack roll change at work. r/millwrights

Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of.

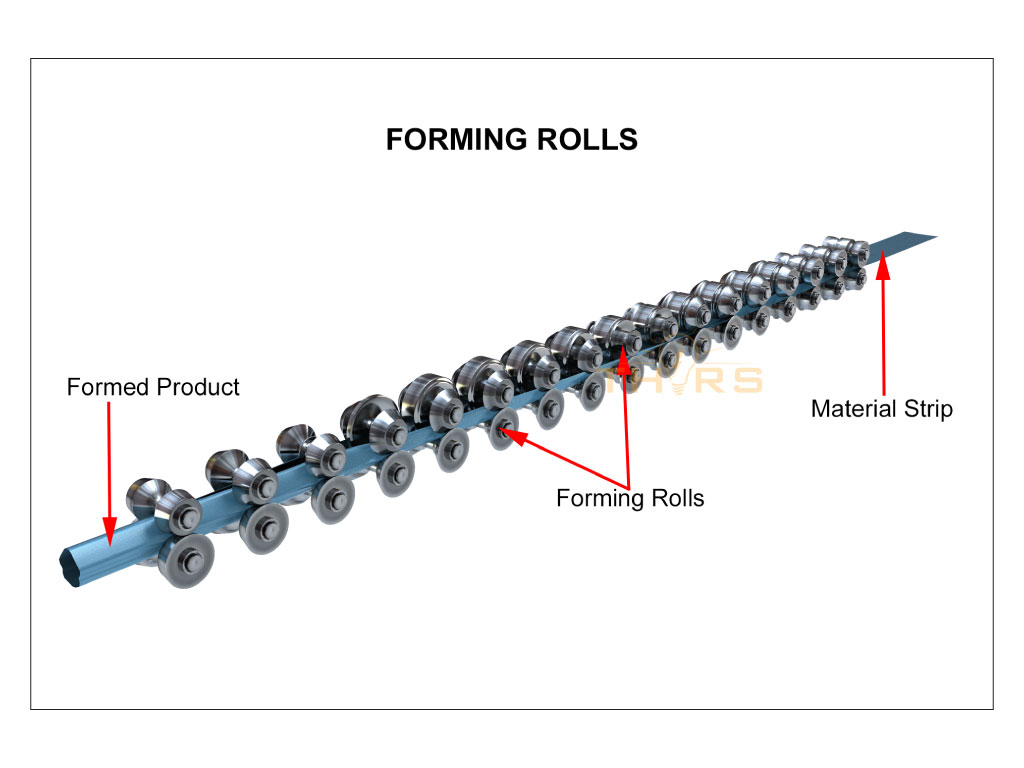

Roll Forming as a Bending Process in Metal Fabrication

Web comprehensive calender roll services. Calenders are sometimes misspelled calendars. Web whether you operate a hard nip machine calender, a soft nip calender or a.

Roll Forming Line Operation and Setup

The rolls in combination are called calenders. Web comprehensive calender roll services. Web basic principle calendaring is the process of squeezing a plastic melt between.

C.N.C. 3Roll Full Automated Specialized Roll Forming System

Web therefore, when calendaring polymers, the material passes three nip regions. Web a calender is a series of hard pressure rollers used to finish or.

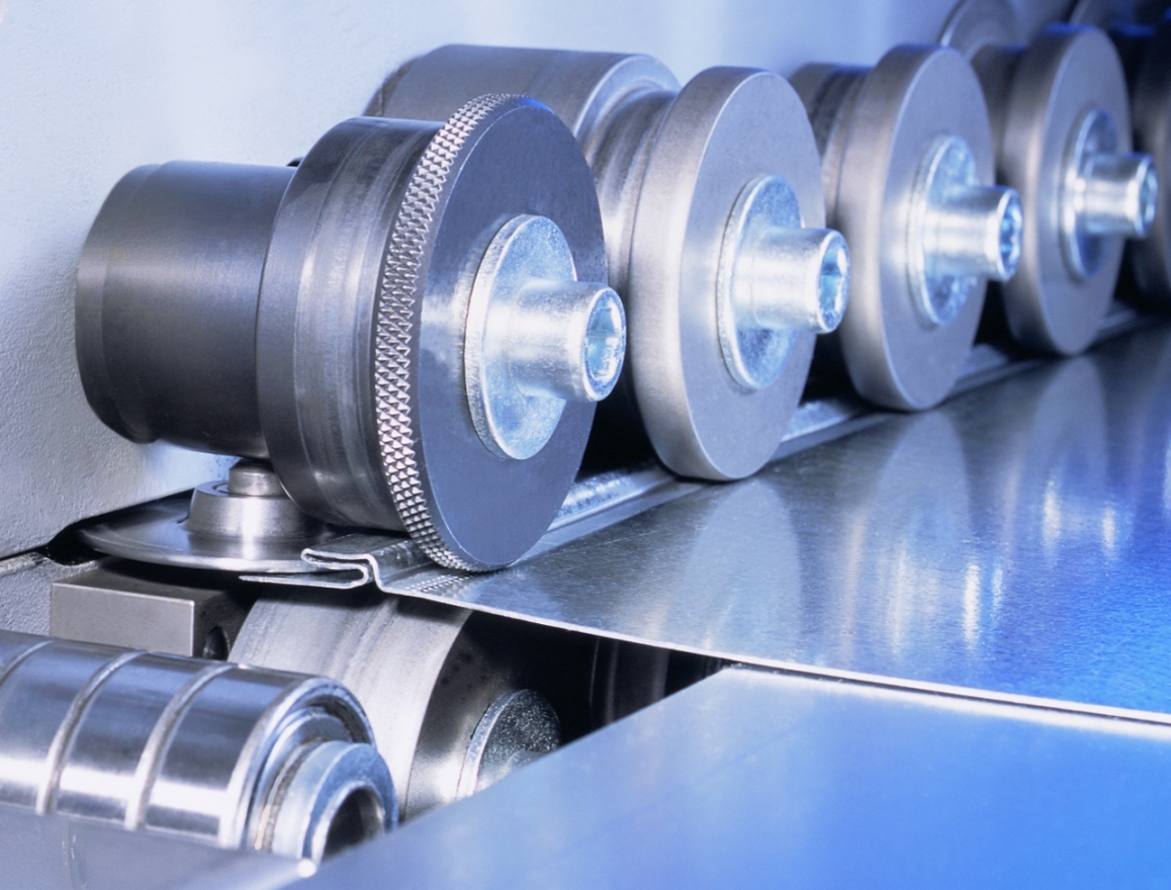

Roll Forming Machine

Web whether you operate a hard nip machine calender, a soft nip calender or a supercalender, our tungsten carbide coatings can provide more consistent paper.

Roll Forming or Press Braking Which is Best for Your Next Fabrication

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or.

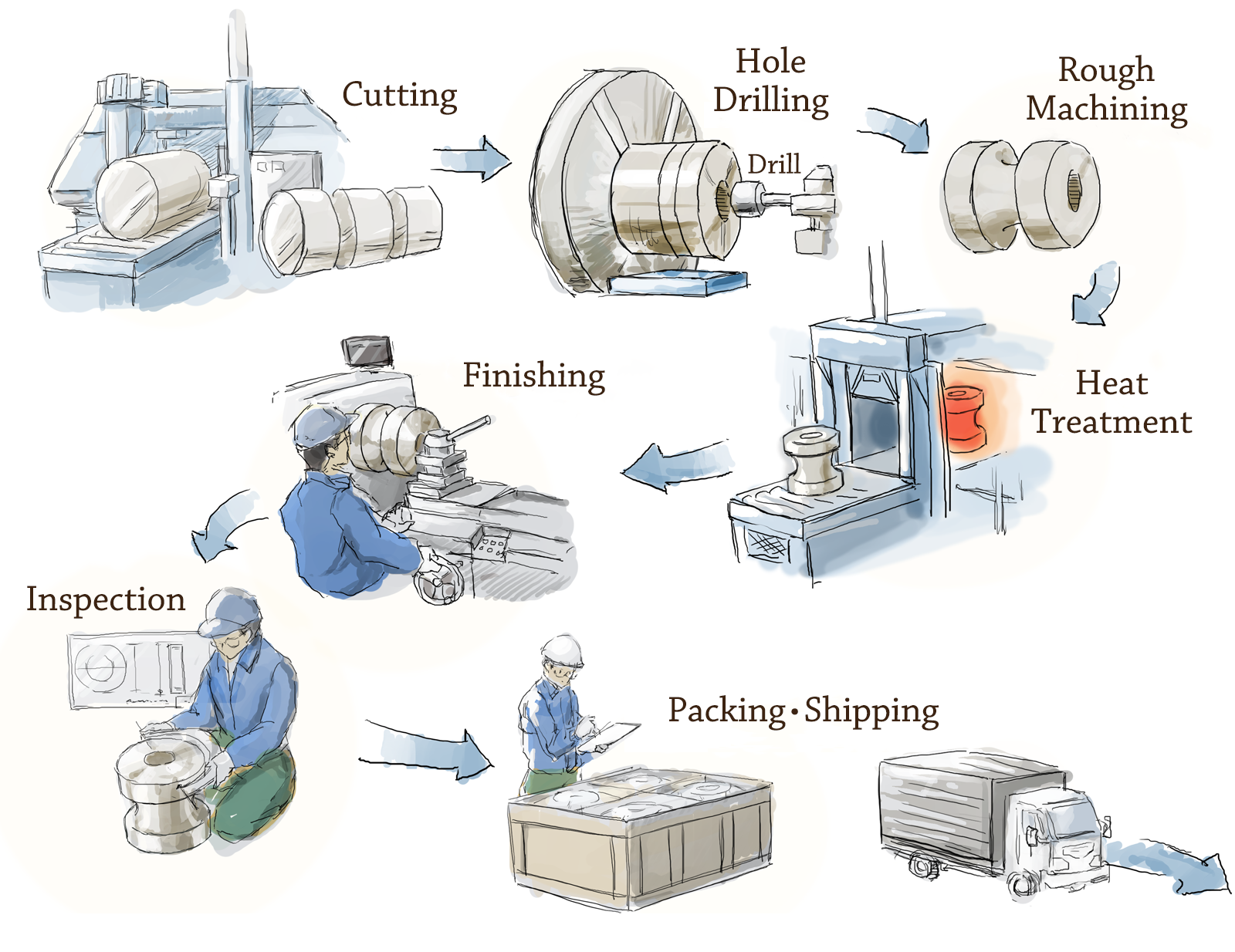

Forming roll|Sanyo Seiki Co.,Ltd.

There are calenders with two, three and four rolls. Web number of rolls, roll diameter, and roll temperature for the calender stack. Valmet’s calender roll.

The Roll Forming Process in 7 Basic Steps

Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of.

The Heavy Sheet Stock Is Passed Through A Series Of Heated, Revolving Calender Rollers Until The Desired Thickness Is Achieved.

Web calenders consist of at least two heatable rolls running in the opposite direction. Residence time may be used to differentiate conveniently between calen dering and milling. The relative importance of these is shown in figures 4 and 5. Involves passing material through heated rollers for enhanced surface finish.

Besides Providing Better Marking Resistance, Our Calender Covers Allow Much Higher Speeds And Temperatures Without Damage Than Conventional Alternatives.

Calenders are sometimes misspelled calendars. The vertical arrange ment of a battery of calender rolls consisting of four or five rolls is commonly employed. Web valmet’s calendering technology provides innovative solutions for all paper and board grades. Web our calender roll services include:

Web Speeds Consistent With Good Stripping From The Final Heated Calender Roll.

Engineering and manufacturing replacement parts. Calenders with five rolls in various arrangements are also used. Figure 5 shows that while a target thickness reduction can be obtained in a number of ways, high temperature calendering gives slightly better smoothness, much better gloss, and a lower strength loss. Calender rolls are constructed of steel with a hardened surface, or steel.

Here, A Previously Unattainable Thickness Range Between 2.

Valmet’s calender roll covers provide longer service intervals and optimum paper or board properties. Calendering is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming composite sheets. The first pass is the ‘‘feed’’ pass, the second, the ‘‘metering’’ pass, and the third, the ‘‘sheet formation, gauging, and finishing’’ pass (1). Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls.