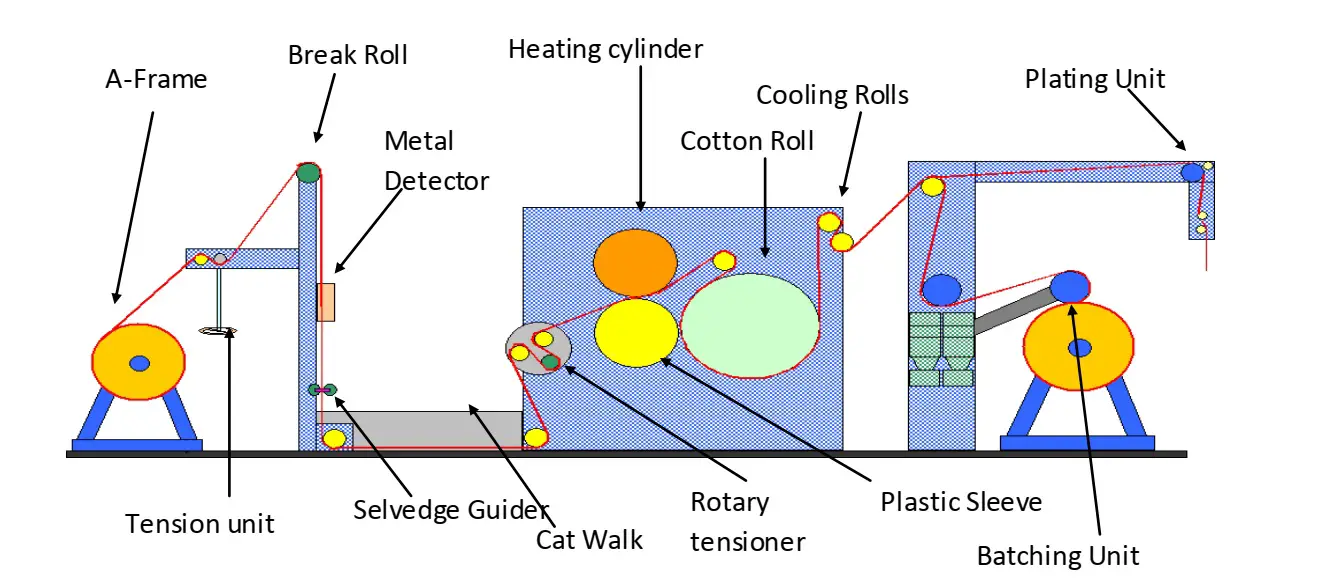

Types Of Calendering - Making plastic film and plastic sheets. Damping can be achieved in 3 ways: They also adhere well to the rollers, allowing them to continue through the chain well, but they don't adhere too well and get stuck on the roller. A suitable degree of dampness. The types of calendaring machines getting used in the industry are given below: Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. It is basically an embossing process. 4 applications of rubber calendering.

Calendering Objective of Fabric Calender Finishing Process YouTube

This simultaneous action is called calendering. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet.

Belt & Ply Calendering ProportionAir

Web calendars fall into four types: Excellent calendering solutions for all paper grades. Each process serves a distinct purpose and imparts unique properties to the.

Calendering Factors Effecting Calendering Calendering Machine

Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. The types of calendaring machines getting.

Calendering

Calendering means the deformation of paper or board under pressure and temperature; Swizzing calendars usually consist of seven to ten bowls. Lunisolar, solar, lunar and.

Nonwoven calendering performs crucial steps in manufacturing

They also adhere well to the rollers, allowing them to continue through the chain well, but they don't adhere too well and get stuck on.

6 Types of Calendering Process in Textile ! Textile Property

Excellent calendering solutions for all paper grades. Damping can be achieved in 3 ways: Swizzing calendars usually consist of seven to ten bowls. With the.

6 Types of Calendering Process in Textile ! Textile Property

Lunisolar, solar, lunar and seasonal. It is basically an embossing process. Web the best polymers for calendering are thermoplastics. With textiles, fabric is passed under.

Types of Finishes Calendering , Tentering, Shrinking , By Suman Meena

Web types of calendaring machines: With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. The types of.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

It is influenced by various additives used in paper production, such as fillers, sizing agents, and dyes, and the fiber type, separation, and mechanical treatments.

The Types Of Calendaring Machines Getting Used In The Industry Are Given Below:

Web there are several different types of calendering, each with its own unique characteristics and applications, including hot calendering, emboss calendering, and compacting. Calendering means the deformation of paper or board under pressure and temperature; Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. With textiles, fabric is passed between calender rollers at high temperatures and pressures.

In The Calendering Process, Molten Plastic Is Extruded And Then Passed Between Pairs Of Heated Rollers That Squeeze The Molten Plastic Into A Sheet.

Web 3 main elements of calendering. Lunisolar, solar, lunar and seasonal. Textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. Web the different calender types.

Making Plastic Film And Plastic Sheets.

There are various calender types, including embossing calenders, friction calenders, swissing calenders, chase calenders, and compaction calenders. Web common types of calendering machine used in the textile industry include: 5 benefits of rubber calendering. A calendar comprises of a number of rows or bowls held in frame.

One Reason For This Is Because They Soften At A Temperatures Much Lower Than Their Melting Temperature, Giving A Wide Range Of Working Temperatures.

A suitable degree of dampness. Excellent calendering solutions for all paper grades. The use of calendering machine to produce flat, compact and polished fabric is very still popular. Calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet.