What Is Calendered Vinyl - Web calendered vinyls are manufactured differently using a rolling process, which is more stressful and results in less dimensional stability of the material. “vinyl” is short for “polyvinyl chloride,” also referred to as pvc, and. This method of creating calendered vinyl gives it the properties described above. It’s a word heard often in the graphics industry. In this video, tyler explains the difference between cast and calendered vinyl and how and when to use it. This makes calendered vinyl decals perfect for flat or curved surfaces. The benefits of calendered vinyl are: The vinyl is cast onto a sheet and then heated to bond with the backing material. Additionally, they are harder to work with and are known for. However, not everyone knows what effects those terms have on buying decisions.

ORACAL® 651 White 010 Intermediate Calendered Film Opaque Craft Film

Cast film is produced by first turning the ingredients of the finished film; Calendared vinyl starts as a solid and goes through rollers to flatten.

Difference Between Cast and Calendered Vinyl S&F Supplies News & Updates

Why should you use cast vinyl? Additionally, they are harder to work with and are known for. Calendared vinyl starts as a solid and goes.

Learn how to tell the difference between cast and calendered vinyl

1.1k views 7 months ago. Calendered vinyl is less durable, less expensive, less flexible, and has fewer applications than cast vinyl. It is also employed.

How Calendered Vinyl Films are Made

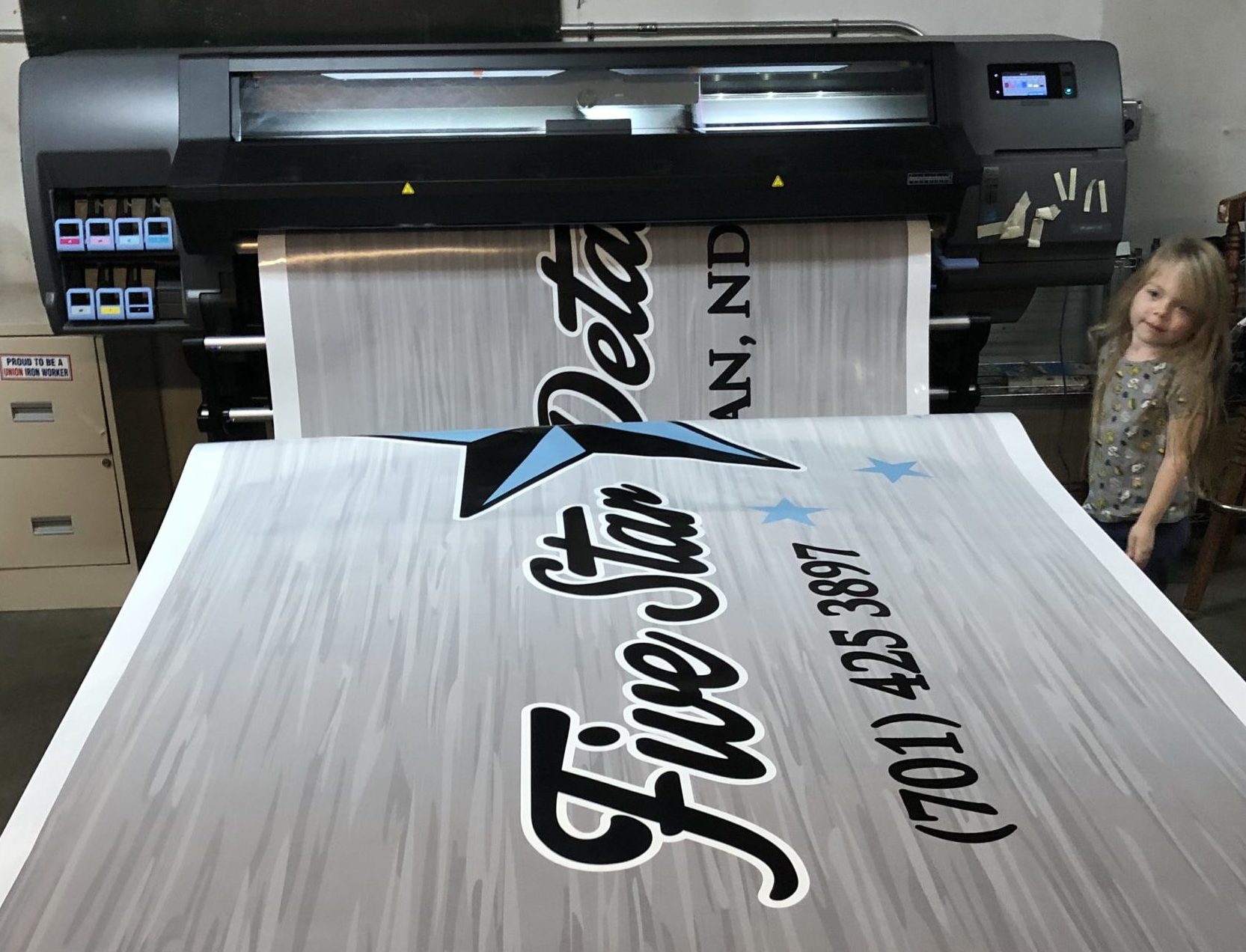

Web what is calendered vinyl? Web calendered vinyl is commonly used in the production of outdoor signs, banners, and vehicle graphics. Web in elementary terms,.

Premium Calendered 3 mil Vinyl with Air Release Overlaminated • Sign Team

Each of these industrial processes can be used to produce a range of film and sheet products with distinct qualities. Web calendered vinyls are manufactured.

Calendered Vinyl Graphics Dollar Signs

Cast vinyl is of higher quality than calendered vinyl, and it’s designed to work on irregular surfaces with minimal shrinkage. It’s a word heard often.

Oracal 651 Calendered Vinyl, 050 Dark Blue, 48" GRAPHIC SOLUTIONS GROUP

Production of calendered vinyl uses similar ingredients, which are mixed and melted to a regulated temperature. It doesn’t stretch as well and is best for.

Calendered Vinyl Shop Calendered Film Rvinyl

It can be highly durable in the right environment. It is usually 2.5 mils to 4 mils thick. This method of creating calendered vinyl gives.

Avery™ HP750 Intermediate Calendered Vinyl

However, not everyone knows what effects those terms have on buying decisions. This makes calendered vinyl decals perfect for flat or curved surfaces. Web calendered.

As With Any Manufacturing Process, There Are Advantages And Disadvantages To Each Approach.

Calendared vinyl starts as a solid and goes through rollers to flatten it out. Web cast or calendered vinyl. The pro’s and con’s of monomeric vinyls. Web there are two main ways to produce vinyl films:

Calendered Vinyl Is Less Durable, Less Expensive, Less Flexible, And Has Fewer Applications Than Cast Vinyl.

Why should you use cast vinyl? Web in elementary terms, calendered vinyl is a type of plastic film that is used for a variety of applications, such as signage, wall graphics, window decorations, and vehicle wraps. Web calendared vinyl is made by squeezing vinyl between heated rollers to fuse the material into sheets. Cast film is produced by first turning the ingredients of the finished film;

Web Calendered Vinyls Are Manufactured Differently Using A Rolling Process, Which Is More Stressful And Results In Less Dimensional Stability Of The Material.

Decals printed on calendered vinyl are much easier to handle and apply than cast vinyl. This method of creating calendered vinyl gives it the properties described above. It is also employed in interior design, as it can be cut into various shapes and applied to a wide range of surfaces, such as walls and windows. In this video, tyler explains the difference between cast and calendered vinyl and how and when to use it.

Each Of These Industrial Processes Can Be Used To Produce A Range Of Film And Sheet Products With Distinct Qualities.

When to use cast or. Cast vinyl uses a process called extrusion coating to create a thicker and more consistent film. It is usually 2.5 mils to 4 mils thick. In this post, we’ll discuss what calendered vinyl is, how it can be applied, and the differences between cast and calendered vinyl.