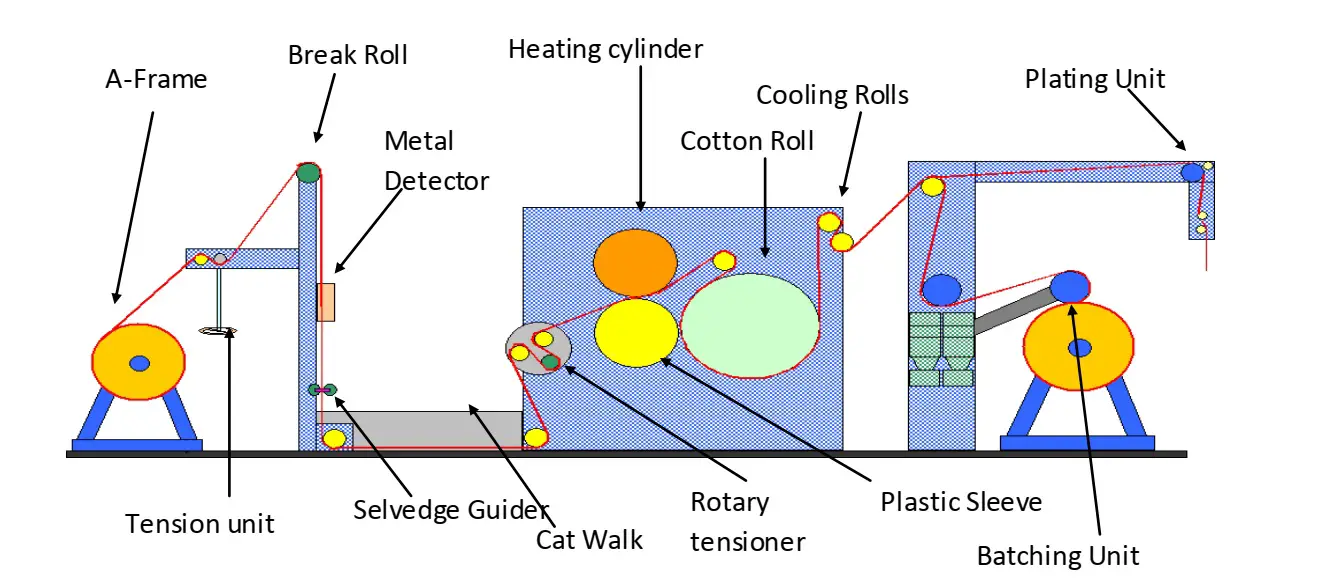

What Is Calendering - This is the technique used to influence the. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is a versatile technique that produces unique finishes on various fabrics, such as more for its watered effect, cambric for a more refined look, and various types. Web calendering is a process in tire manufacturing where steel or fabric is coated with rubber. Calendering was originally developed to process rubber, but today is widely used to make thermoplastic films, sheets, and coatings. Web a calender is a device used to process a polymer melt into a sheet or film. Web calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure and a suitable degree of dampness. Steel belts, body plies, cap plies, and belt edge covers are all produced using the. Web calendering is a finishing process used on cloth and fabrics. With textiles, fabric is passed under rollers at.

Calendering for Filter Cloth Finishing Micronics Inc

Steel belts, body plies, cap plies, and belt edge covers are all produced using the. The main function of calendering is to provide a smooth.

Nonwoven calendering performs crucial steps in manufacturing

Web a calender is a device used to process a polymer melt into a sheet or film. Web calendering is a continuous process where melted.

Belt & Ply Calendering ProportionAir

Web the calender is a series of hard pressure rollers used to form or smooth a sheet of material. Web calender, machine that has wide.

Calendering Objective of Fabric Calender Finishing Process YouTube

Web produce pvc film and sheet in large quantities, calendering is almost always used since the process is less likely to cause degradation than is.

Calendering

Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure.

An overview of calendering (or rolling) like processes YouTube

The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web..

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING

Web with a cd, you essentially loan money to a bank or credit union for a set period. Web calendering is a finishing process used.

Calendering Rubber YouTube

Web calendering is a continuous process where melted plastic, paper, rubber or fabrics are squeezed between pairs of rollers. This is the technique used to.

6 Types of Calendering Process in Textile ! Textile Property

With textiles, fabric is passed under rollers at. Web the calender is a series of hard pressure rollers used to form or smooth a sheet.

With Textiles, Fabric Is Passed Under Rollers At.

Web calendering may be defined as the modification of the surface of a fabric by the action of heat and pressure. The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web. Calendering finishing is a process of imparting luster and smoothness to a. Web produce pvc film and sheet in large quantities, calendering is almost always used since the process is less likely to cause degradation than is extrusion as well as having.

Web Calendering, Process Of Smoothing And Compressing A Material (Notably Paper) During Production By Passing A Single Continuous Sheet Through A Number Of Pairs Of Heated.

Web calendering is a process in tire manufacturing where steel or fabric is coated with rubber. It has been in use for over a hundred years and when first developed it was mainly used for processing. The main function of calendering is to provide a smooth fabric surface, light lustre, and improved hand. Web calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create.

Steel Belts, Body Plies, Cap Plies, And Belt Edge Covers Are All Produced Using The.

When carried out on a paper machine, it is called. Web with a cd, you essentially loan money to a bank or credit union for a set period. A calender is employed, usually to smooth, coat, or thin a material. Calendering is one method of making plastic.

In Exchange, The Bank Gives You A Fixed Return On Your Deposit.

With textiles, fabric is passed between calender rollers at high temperatures and. Web calendering is a versatile technique that produces unique finishes on various fabrics, such as more for its watered effect, cambric for a more refined look, and various types. Web calendering leaves a significant imprint on the microstructure of battery electrodes. Web in paper manufacturing, calendering is the process of smoothing the surface of paper by pressing it between metal cylinders or rollers (calenders) at the end of the.